Little Known Facts About Glazed Glass Panels.

Table of ContentsGlazing Infill Panels Fundamentals ExplainedThe 8-Minute Rule for Glazing Infill PanelsThe Main Principles Of Insulated Glazing Panels

The service life span of parts that are mated with the drape wall into an assembly must match the life span span of the drape wall itself. Require durable flashing products, non-corroding accessory hardware and fasteners, and moisture resistant products in areas subject to moistening. Lab testing: For tasks with a considerable quantity of custom drape wall, need laboratory testing of a mock-up drape wall prior to settling job store illustrations.

Define that laboratory tests are to be performed at an AAMA Accredited Lab center. Field Mock-up: For all drape walls, stock or custom-made, require construction and screening of a field mock-up representative of the wall/window assembly. This is finest arranged prior to the release of store drawings for window production, so that there is a chance to make style changes based on the test performance of the field mock-up.

Field screening of curtain walls: Need the field screening of drape walls for air infiltration and water penetration resistance, for quality control of curtain wall fabrication and installation. Require several tests with the very first test on initial setups and later tests at roughly 35%, 70% and at last conclusion to catch issues early and to validate ongoing craftsmanship quality - glazing panel.

Shop drawing coordination: Need drape wall installation store illustrations revealing all adjacent construction and associated work, consisting of flashings, accessories, interior surfaces, and showing sequencing of the work. Drape wall systems, specifically unitized systems, require expertise on the part of the structure designer, the producer, the fabricator, and the installer. For all but the most basic of systems, the designer needs to consider engaging an outside expert, if such know-how is not readily available on the staff.

The Facts About Glazed Glass Panels Revealed

The details connected with this area of the BEDG on the WBDG were established by committee and are intended solely as a means to illustrate basic style and building and construction principles only. Proper usage and application of the principles highlighted in these details will differ based upon performance factors to consider and ecological conditions distinct to each task and, therefore, do not represent the last viewpoint or recommendation of the author of each section or the committee members accountable for the advancement of the WBDG.

Elevation includes splice joints to accommodate thermal motion of the drape wall find frame. A through-wall metal flashing at the base of the brick cladding above the curtain wall safeguards the drape wall from leakage through the wall above (see Outside Wall) for integration of the these elements. Find exterior border sealant joints behind trim cover to prevent water inside trim cover from bypassing the outside sealant joint.

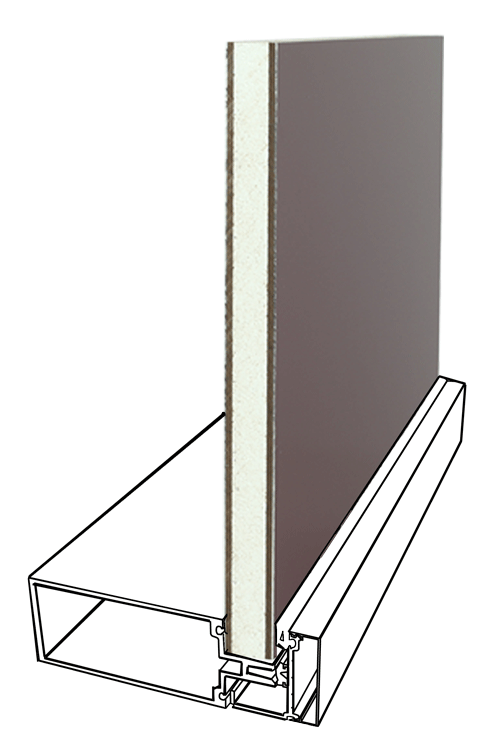

Locate setting blocks as to not block water drain from the glazing pocket. Offer anti-walk blocks at the jambs of the glazing systems. Blocks need to be gapped 1/8-inch from the edge of the glazing unit. Note: the following U-series information are courtesy of The Exterior Group This elevation reveals a common unitized curtain wall assembly hung from the edge of the floor piece.

Unknown Facts About Large Glazing Panels

Spandrel glass adapters are utilized to lower the depth of the glazing pocket to accommodate lowered profile of spandrel glass. Spandrel glass adapters need to be totally bedded in sealant and incorporated with glazing pocket corner seals to prevent water leak from glazing pocket to structure interior. System dimension of mating head and sill extruded profiles permits defined flooring to flooring deflection at the stack joint.